-

Telecommunication

-

Fiber Optic Cables

-

< div class="menu-icon">

Conventional Cables

Conventional Cables

-

< div class="menu-icon">

OPGW

OPGW

-

< div class="menu-icon">

ADSS

ADSS

-

< div class="menu-icon">

Submarine

Submarine

-

< div class="menu-icon">

WTC (World's Highest Density)

WTC (World's Highest Density)

-

< div class="menu-icon">

-

Optical Fibers

-

< div class="menu-icon">

Single Mode

Single Mode

-

< div class="menu-icon">

Multi Mode

Multi Mode

-

< div class="menu-icon">

Specialty Fibers

Specialty Fibers

-

< div class="menu-icon">

-

Fiber Splicing Machines & Related Products

-

< div class="menu-icon">

Telecommunication Fibers

Telecommunication Fibers

-

< div class="menu-icon">

Specialty Fibers

Specialty Fibers

-

< div class="menu-icon">

-

Optical Test Equipment

-

< div class="menu-icon">

OTDR

OTDR

-

< div class="menu-icon">

Portable Power Meters & Light Sources

Portable Power Meters & Light Sources

-

< div class="menu-icon">

-

Installation Accessories For F/O Cables

-

< div class="menu-icon">

Installation Accessories For F/O Cables

Installation Accessories For F/O Cables

-

< div class="menu-icon">

-

Tools

-

< div class="menu-icon">

For Fiber Optic Cables

For Fiber Optic Cables

-

< div class="menu-icon">

-

Fiber Inspection & Cleaning Products

-

< div class="menu-icon">

Fiber Inspection

Fiber Inspection

-

< div class="menu-icon">

Cleaning Kits

Cleaning Kits

-

< div class="menu-icon">

Push-Type Cleaners

Push-Type Cleaners

-

< div class="menu-icon">

Reel-Type Cleaners

Reel-Type Cleaners

-

< div class="menu-icon">

Fiber Optic Cleaning Fluids

Fiber Optic Cleaning Fluids

-

< div class="menu-icon">

Wipes & Cleaning Cards

Wipes & Cleaning Cards

-

< div class="menu-icon">

Cleaning Sticks,Tips & Swabs

Cleaning Sticks,Tips & Swabs

-

< div class="menu-icon">

-

Optical Components

-

< div class="menu-icon">

Central Office Application

Central Office Application

-

< div class="menu-icon">

Optical Cabinets

Optical Cabinets

-

< div class="menu-icon">

High-Rise Building Solutions

High-Rise Building Solutions

-

< div class="menu-icon">

Demarcation Boxes & Optical Outlets

Demarcation Boxes & Optical Outlets

-

< div class="menu-icon">

Optical Splitters

Optical Splitters

-

< div class="menu-icon">

Optical Closures

Optical Closures

-

< div class="menu-icon">

-

- Fiber In Medical

Fiber Splicing Machines & Related Products

Clad Alignment Fusion Splicer 45S Kit

Product code : W0A7DB

Clad Alignment Fusion Splicer 45S Kit The 45S is the essential splicer based on active clad alignment technology with features, Fast Operation, User-friendly Design, Versatile Functionality and Consistent Quality.

Faster operation

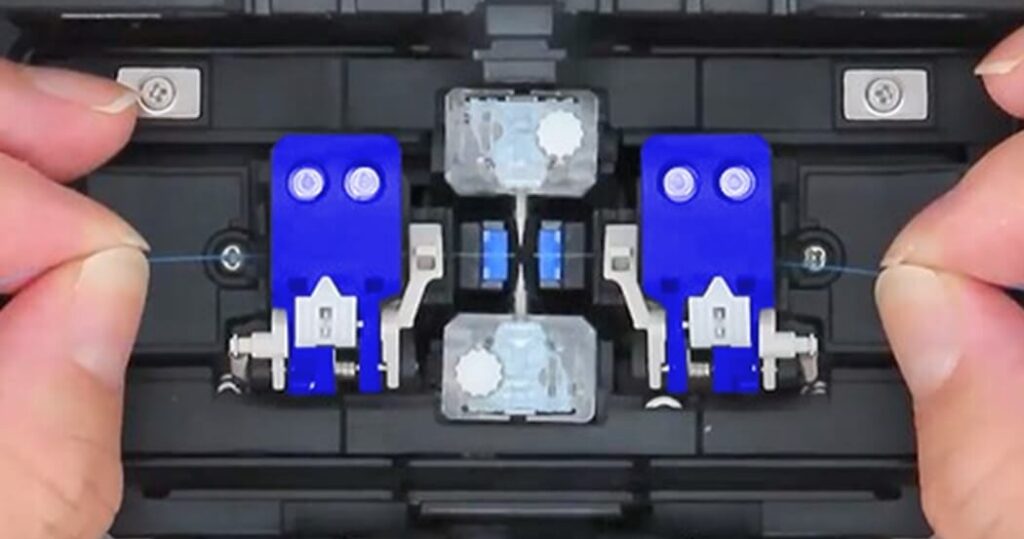

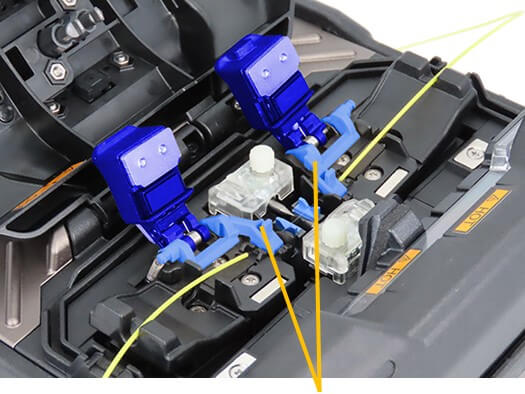

■Simultaneous fiber preparation

Fiber preparation, stripping, cleaving, and setting in the splicer usually needs repeating separately for both left and right-side fibers. The 45S process does away with that and enables simultaneous fiber preparation thanks to the new SS05 double fiber stripper, the new AD-60A fiber adapter for the CT60 cleaver and the clever set plate mechanism of the 45S itself.

●Simultaneous fiber stripping

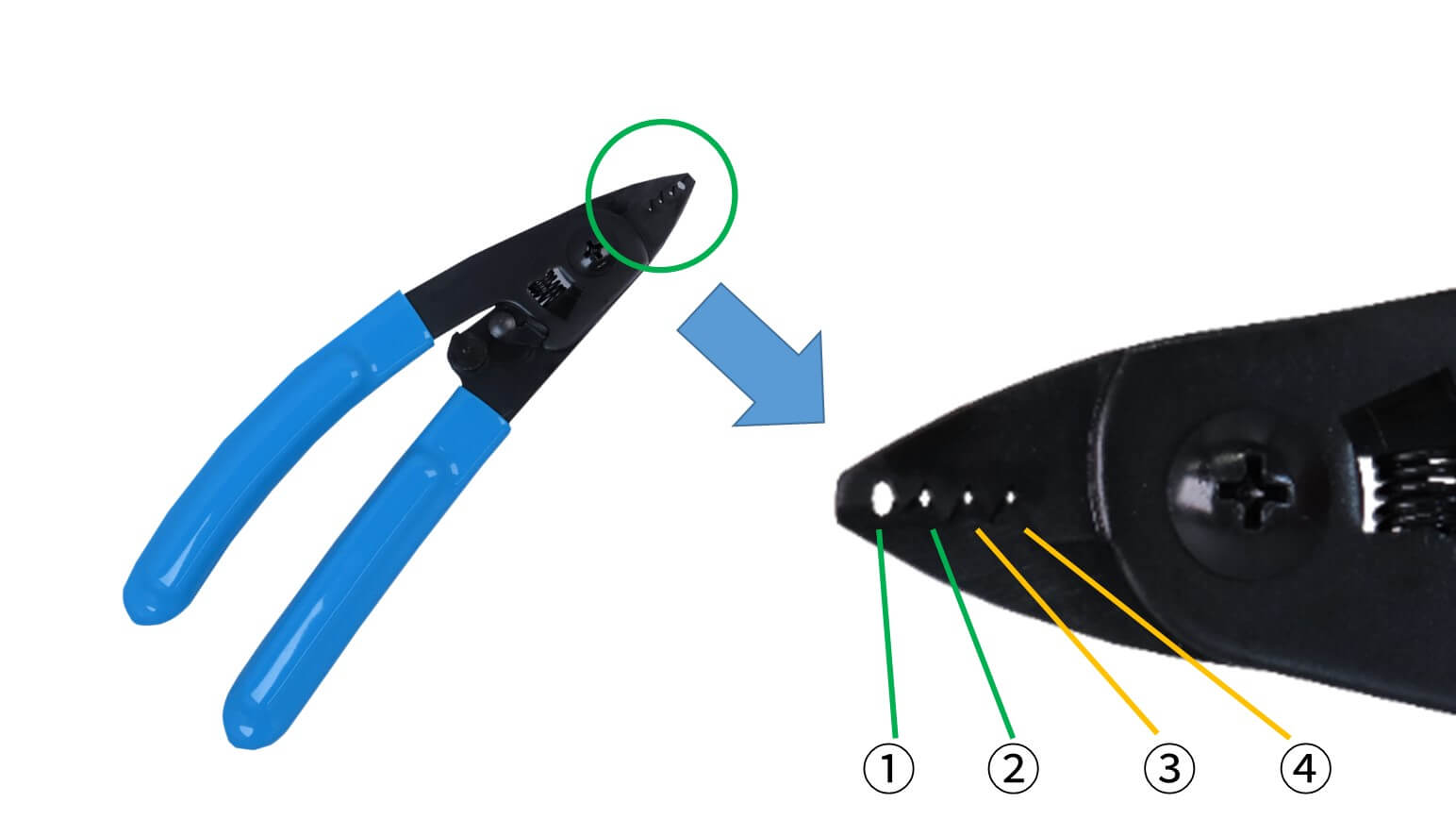

The SS05 fiber stripper is equipped with four blades:

① for 2mm/3mm, ② for 900µm, ③④ for 250µm fibers. Using blades ③ & ④ allows simultaneous stripping of 250µm fibers.

Fiber Stripper SS05

●Simultaneous fiber cleaving

The new AD-60A fiber adapter for the CT60 cleaver is equipped with two grooves. Placing one fiber in each groove provides simultaneous cleaving.

Optical Fiber Cleaver CT60

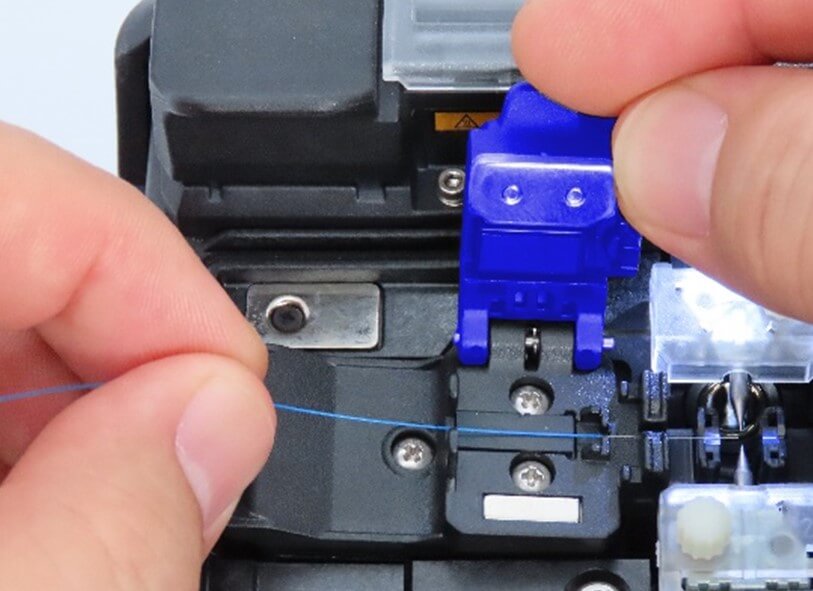

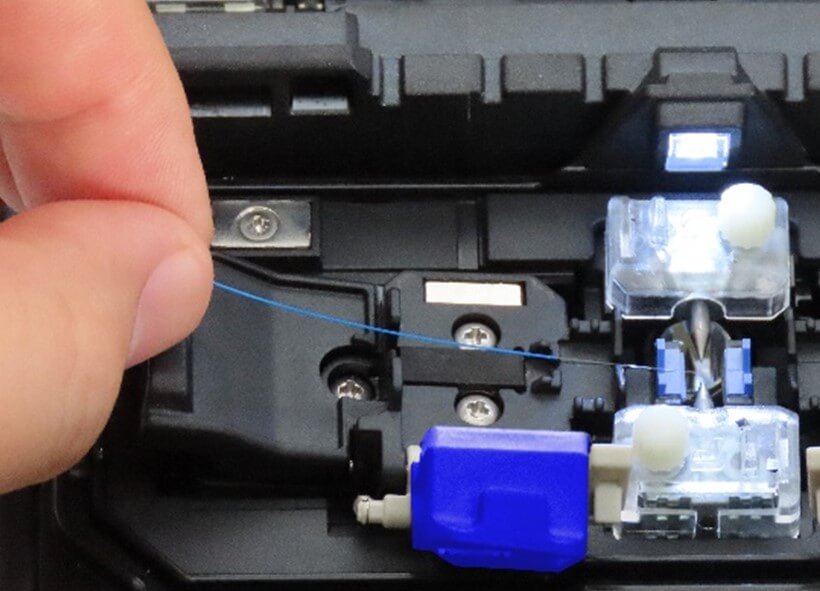

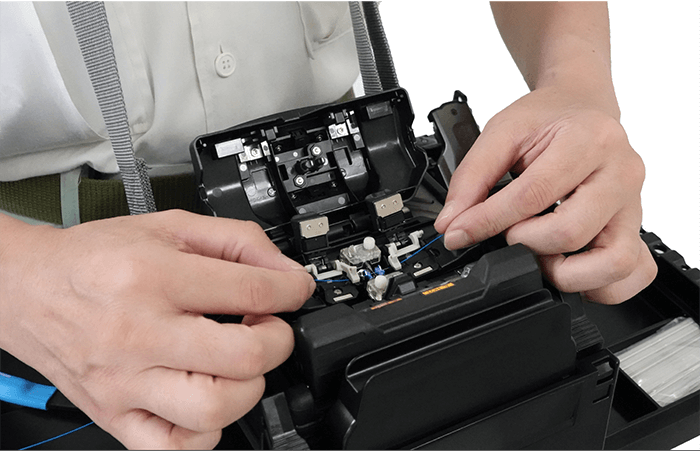

●Simultaneous fiber setting

Previous fusion splicers required two-handed operation to close fiber clamp and hold the fiber. Thanks to a new clamp mechanism, the 45S close with fiber setting and provides one-handed fiber setting and simultaneous fiber setting.

New clamp mechanism

Previous Model

Two-handed

45S

One-handed

45S

Simultaneously fiber setting

■Faster fiber transportation time

The 45S is equipped with a mechanism linking the wind protector and fiber clamp so when you open wind protector, the fiber clamps opens automatically.

The 45S is also equipped with retention clamps which are reputed by our conventional fusion splicer models. The retention clamps prevent the fiber from jumping out after the fiber clamps are opened.

These mechanisms work in tandem to provide easy fiber handling and a reduction in the time it takes to transfer the fiber to the heater.

Interlocking mechanism with fiber clamp

Fiber retention clamps

■Faster heating time

The heater for shrinking the reinforcing sleeve is designed to heat the reinforcing sleeve between two heaters in the front and rear. It shorten 15% of the heating time in case of using FP-03 sleeve.

※Measured at room temperature with the AC adapter. The heat time is defined from the start beep sound to the finish beep sound. The average heat time changes depending on the environmental conditions, sleeve type and battery pack condition. In addition, since the heating operation is constantly optimized, the average heating time changes depending on the usage conditions of the fusion splicer.

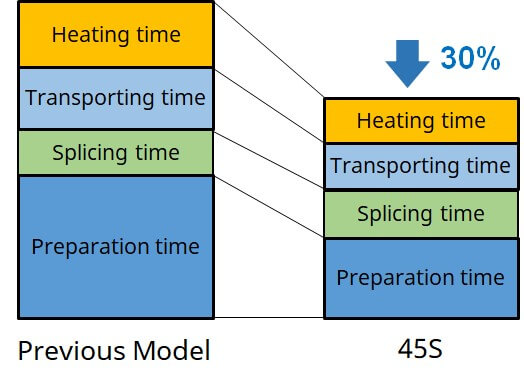

■30% faster than previous model

Thanks to the way the 45S streamlines the preparation process, reduces transport time and delivers faster heating, it is 30% faster than the 41S+ it replaces.

User-friendly design

■Movable LCD Monitor

The 45S is equipped with a 4.95 inches size movable LCD monitor.

It provides visibility especially for outside use even though under the sunshine.

■Easy Sleeve Positioning

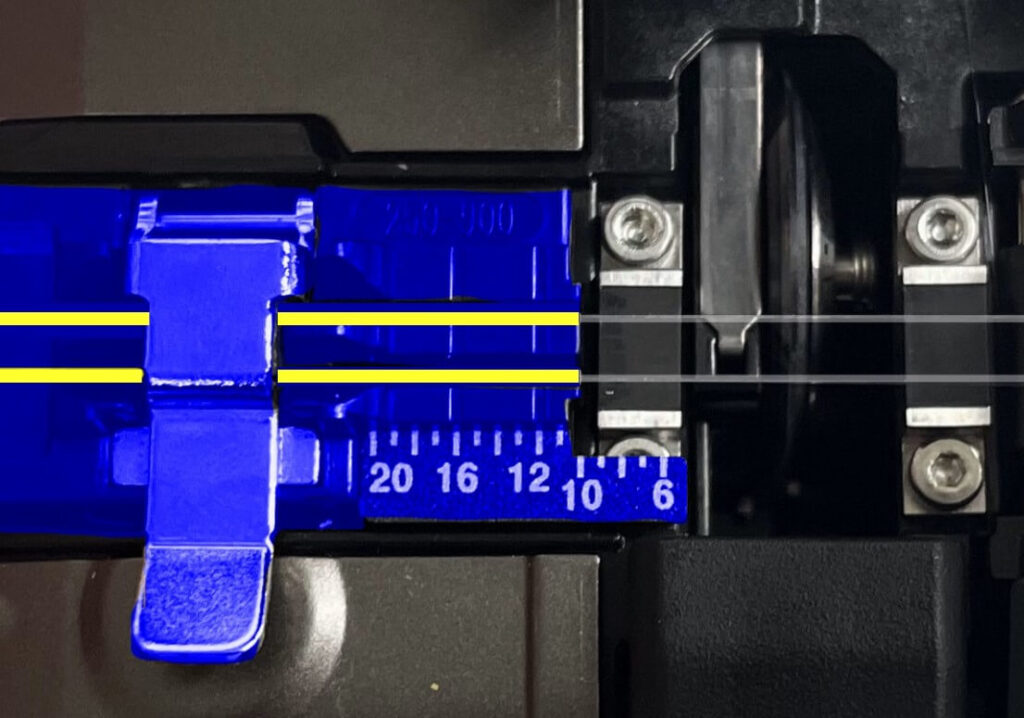

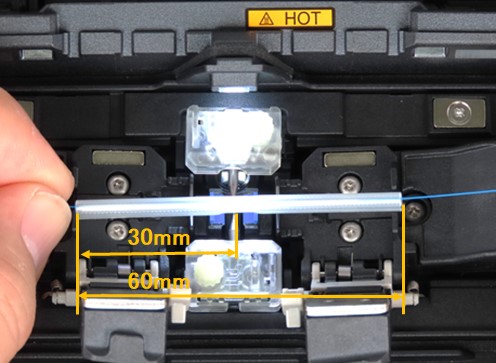

The space between the edges of the left and right fiber clamp edges is 60mm, as per the image to the left.

This distance allows for easy sleeve positioning, with the splice point positioned in the middle of the sleeve.

The scale on the heater shows the guide for other sleeve lengths, for example 40mm.

■Removable battery

■Cubic Shape

The removable battery makes replacement easy and convenient.

The cube shape provides a reduced base area while also giving the user a large operating space.

Previous Model

40% reduced base areas

45S

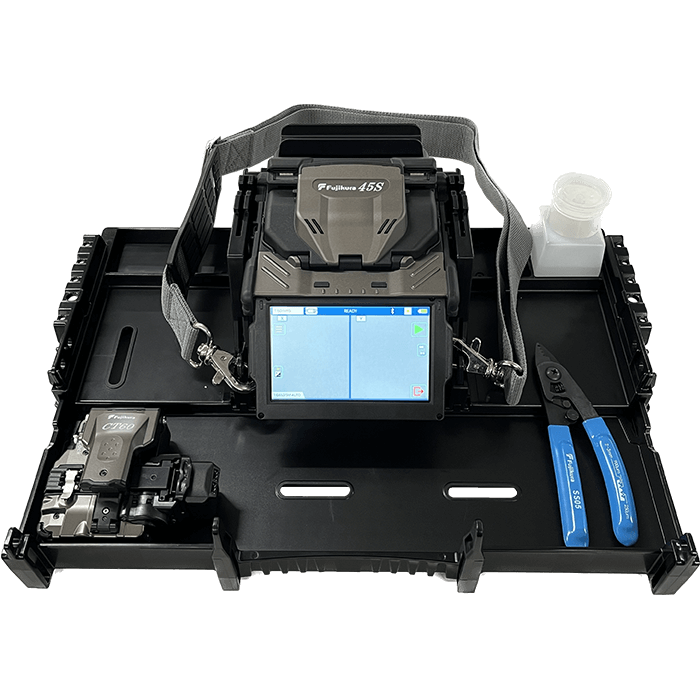

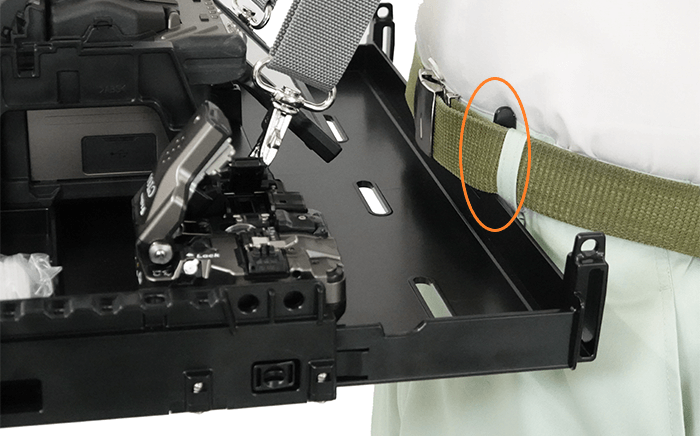

■Carrying case with Work Tray

The configurable 45S carrying case provides various usage configurations.

Configuration example 1

Open the carry case and start operation.

Configuration example 2

Remove the work tray and put on top of the carry case.

Removing the work tray from the carry case allows the tray to expand. Using the work tray with the strap provides a portable work surface and the strap can be fixed to the work tray at the sides of the splicer to secure the usability

Secure working space

Increased security when used with a belt

Consistent quality

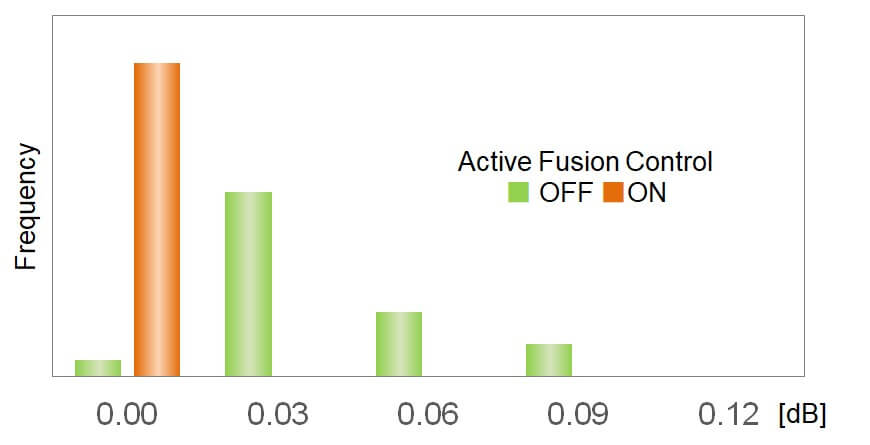

■Active Fusion Control

The 45S is equipped with Fujikura Active Fusion Control Technology, which analyses the fiber image during fusion and controls the arc discharge accordingly. The result is stable splice loss irrespective of the environment.

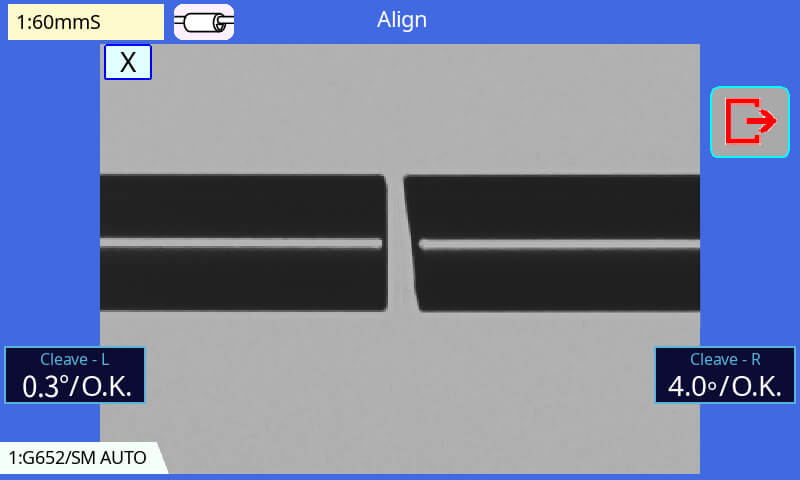

●Control by Fiber Cleaved Surface

A bad cleave end face is a potential reason for high splice loss. The 45S can address this because it’s equipped to control fusion according to the condition of the cleaved surface. This function helps reduce splice loss by compensating for poor cleaves.

Splicing loss of cleave angle fiber: 3°<θ<5°

*Fujikura test result of ITU-T G652 fibers measured by cut-back method.

The splice loss may vary depending on operating environment or fiber characteristic.

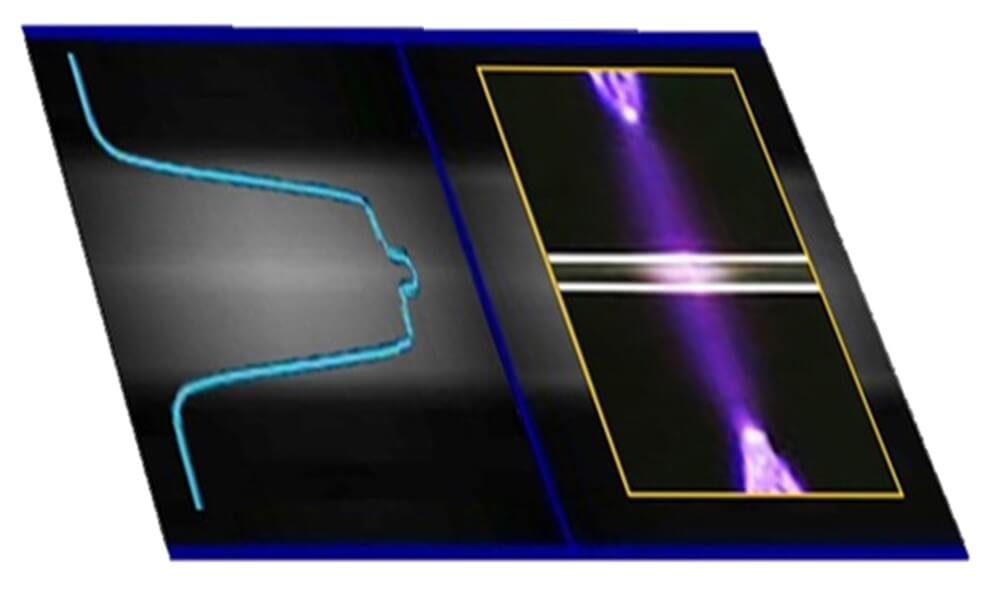

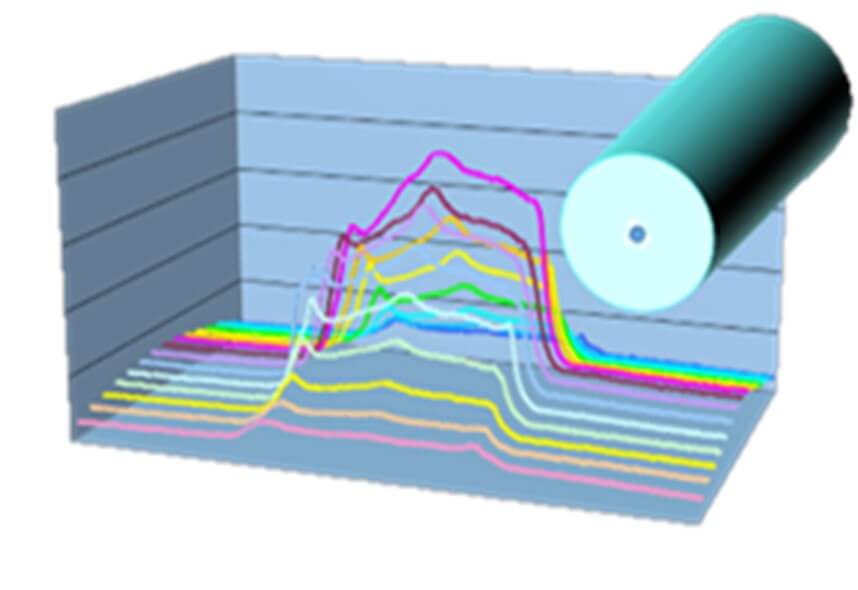

●Real-time fusion control

The 45S analyses the fiber image during fusion and controls fusion power according to the real-time condition of the fiber. This helps to minimize splice loss irrespective of the environment.

Analyzing fiber image during fusion

This process also provides Warm Splice Image (WSI) technology. WSI analyses during the splice and provides loss estimation, even though the 45S is a clad alignment splicer.

It would help to prevent the case of “good loss estimation but bad actual loss”.

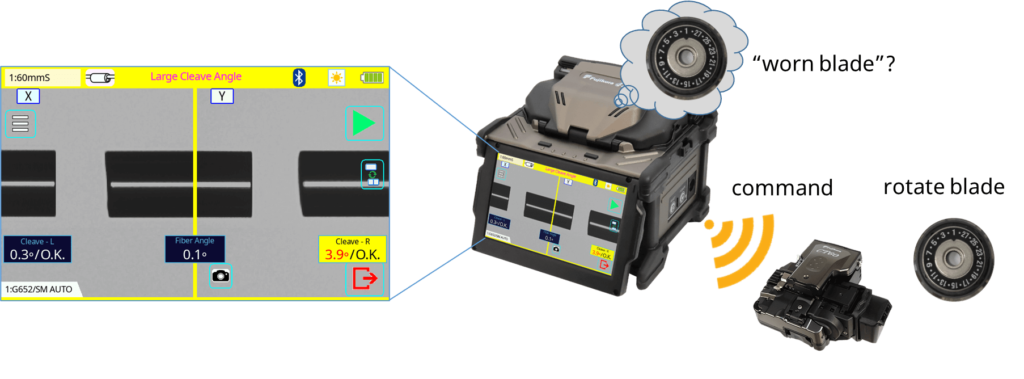

■Active Blade Management

The 45S monitors the blade condition of the CT60 cleaver via wireless communication. When the 45S judges that the blade is worn, it will command the CT60 to rotate the blade to a new position to ensure the CT60 keeps delivering consistent cleaving performance.

SIMILAR PRODUCTS

The 90R12 is a mass fusion splicer capable of splicing up to 12 fiber ribbon cables simultaneously. In previous mass fusion splicer models, the v-grooves could become dirty over time due to debris and glass deposits from splicing accumulating in the v-grooves. Which in turn, could lead to fibre offsets and high losses if they were not regularly cleaned which added to the overall process time. The 90R12 comes with a first of its kind, innovative user replaceable V-groove assembly which makes this issue a thing of the past and is supplied as standard equipment with the 90R12 kit. This new V-groove assembly can be quickly and easily fitted in the field, minimizing downtime and maximising productivity. In addition, the new V-groove design enables splicing of both conventional type 12-fiber encapsulated ribbon and SWR (Spider Web Ribbon) whilst also accommodating 250um and 200um pitch fibers. The 90R12 can also splice single fibers if required. also making use of Active Blade Management Technology, which now can connect to two CT50 cleavers simultaneously.

Item Successfully Added to Cart

The 41R is a equipped with good mobility and our wireless communication function, “Active Blade Management Technology”, where the splicer is connected to and monitors the fiber cleaver and ribbon fiber stripper With Active Blade Management Technology, it is far easier to maintain high quality fiber preparation. This product monitors every fiber’s end shape to assess the cleave quality. If the cleaved fiber is bad due to a worn blade position, this product sends a command to the fiber cleaver to rotate to the next viable blade position. The cleaver then executes the blade rotation automatically via an internal motor. This functionality greatly prevents operators from making a bad splice due to a worn out blade position. In addition, both the heating temperature and heating time of the ribbon fiber stripper are automatically changed according to the splice mode setting.

Item Successfully Added to Cart

Fujikura 99S Fusion Splicer Features Automated wind protector, tube heater and splice operation Dual fiber loading reduces preparation time Embedded fiber guide for accurate, error-free fiber loading Built-in Splice Coach virtual mentor to improve productivity Custom Splicer Setup menus with new UI and visual diagrams GPS splice stamp for location record keeping Location Based Locking prevent unauthorized use or theft USB-C charging and data port Multi-function transit case with integrated workstation Applications Distribution fiber repair Long-haul network installation Field termination with splice-on connectors Access network installation Fanout kits, pigtails and splice cassettes OSP cable installation and repair Optical modules – splitters, couplers, MUXs, EDFAs and attenuators

Item Successfully Added to Cart

Features Motorized blade rotation Bluetooth communication Shock resistant Simple one-step operation 60,000 cleave blade life Field serviceable PRODUCT DESCRIPTION The Fujikura CT60 Fiber Cleaver is engineered for precision and durability, offering motorized blade rotation and Bluetooth connectivity for seamless integration with compatible Fujikura splicers. Designed to support both single and ribbon fibers, it delivers consistent cleave quality with minimal maintenance and an impressive blade life. One-Handed Operation: Designed for ergonomic use, the CT60 supports one-handed operation with a simplified cleaving mechanism and a toggle button for flexible arm control. Motorized Blade Rotation: The CT60 features fully automatic blade rotation, ensuring consistent cleave quality and extending blade life up to 60,000 cleaves. Bluetooth Connectivity: Seamlessly integrates with compatible Fujikura fusion splicers via Bluetooth, enabling smart blade management and maintenance tracking directly through the splicer. Dual Cleaving: Capable of cleaving two optical fibers simultaneously, the CT60 significantly improves efficiency for technicians working with ribbon or paired fibers. Expanded Blade Positions: With 28 cleaving positions, the CT60 eliminates the need for blade height adjustments, allowing finer control and easier maintenance. Easy Maintenance: The CT60 fiber cleaver has a user-replaceable blade, so there’s no need to send the device to a service center for blade or clamp replacement. Drop-Tested Durability: Engineered to withstand drops up to 30 inches, the CT60 sets a new standard for ruggedness in fiber cleavers, making it ideal for field use. Active Blade Management Technology: Automatically advances blade positions based on cleave count or quality, ensuring optimal performance without manual intervention. Versatile Fiber Compatibility: Supports single-mode and multimode fibers, including single and ribbon configurations up to 16 fibers, with a wide range of coating diameters and fiber holders. Compact and Lightweight Design: With a palm-sized design and a weight of just 280 g (including battery), the CT60 is portable and easy to handle in any environment. User-Replaceable Blade and Components: Simplified maintenance allows users to replace blades and clamps in the field, reducing downtime and service costs.

Specification Sheet

Specification Sheet